You’d better use the CNC software to control CNC mills and other types of CNC machines. Such programs make it easier to convert a model or motor movement. They allow combing motors, rails and a 3D model. With them, you can improve machine automation. Thanks to these programs, you can improve your engraved products.

With Fusion 360, my team and I can jump into our projects from any device, share our designs with stakeholders, and collaborate in real-time. Thus, our productivity improves and we can get along without face-to-face meetings.

The CNC fabrication industry keeps pushing forward and CAD/CAM software is undoubtedly a linchpin in modern manufacturing. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are core elements of CNC machining. They make the production faster, more precise, and efficient.

CAD/CAM software forms the bedrock of CNC fabrication. Such programs help make intricate 3D models (CAD), which are then transformed into instructions readable by machines (CAM) to direct the CNC equipment. This mechanical engineering software covers a broad spectrum of tasks, from CNC milling and turning to detailed surface finishing.

Whether you're working with metals like aluminum or stainless steel, or dealing with wood or plastics, it is paramount to have good CAD/CAM software. Thus, you can be sure you’ll get accurate and steady results. Besides, such tools speed up production and lower the risk of mistakes.

I have tested and experimented with various CNC software options. Now I have my own set of guidelines for choosing the best CNC router software.

1.It's important to know which CNC techniques the software supports. Some programs specialize in certain CNC methods, like milling, lathe work, plasma cutting, or woodworking. For instance, free woodworking design software for CNC may not offer the same features as top-notch 5-axis CAM software. So, it's crucial to understand if the software matches your CNC technique.

2.Diverse features and capabilities. When choosing CNC software, it's vital to look at what it can do. Whether you're drawing up basic 2D designs or tackling intricate 3D models, the software should have the right tools for the job. For instance, 3D modeling software is the way to go if you want to make detailed designs for your CNC router or mill.

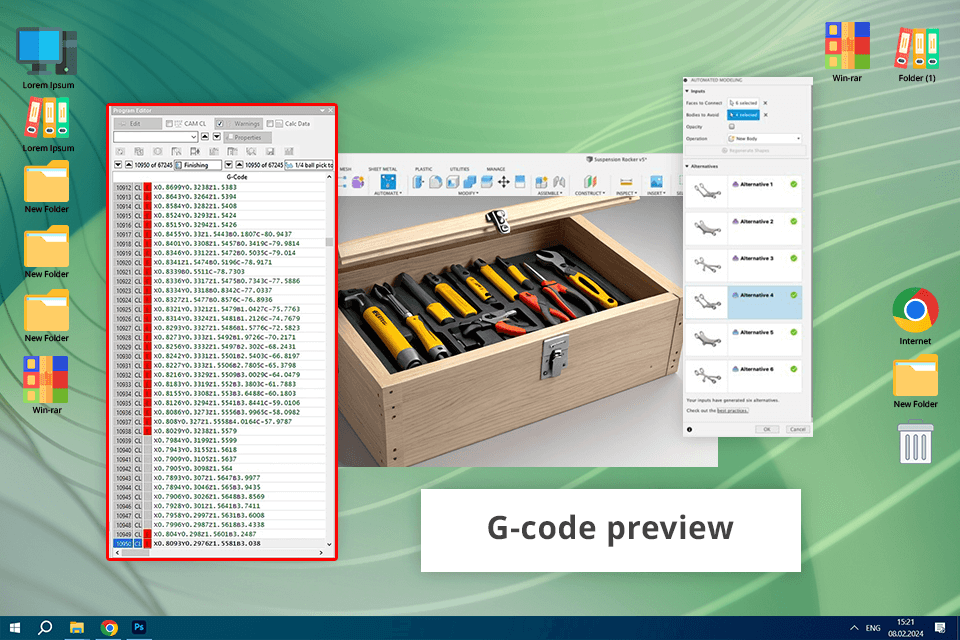

3.Possibility to import and export different formats. This way, you have more room to maneuver when working with various design tools or sharing your designs with clients or teammates. The top-notch CNC software should handle multiple file formats (like G-code, DXF, STL, IGES, STEP, DWG, HPGL, etc.).

Integration with other apps. Another key point to think about is how well the software meshes with other tools you use, like design software or CNC controllers. For example, if you leverage open source CAD software, it should fit together smoothly with your chosen CNC control or programming software. This is paramount for making your design and manufacturing tasks run more smoothly and swiftly.

Autodesk Fusion 360 is very popular CAD/CAM software for CNC tasks. It's all packed into one cloud-based platform, which is super handy. Fusion 360 contains multiple tools that blend CAD, CAM, and CAE. There are also strong 3D modeling tools and a wide range of CAM programs to turn your models into instructions for CNC machines. Plus, it comes with simulation features to make sure your toolpaths will deliver exactly what you're aiming for.

One more thing that convinced me to download Fusion 360 is its ability to work on different platforms. I needed CAD/CAM software for CNC routers or 3D printers, and Fusion 360 exceeded my expectations in completing these tasks. To my mind, it can come in handy for various uses, including the production of detailed woodworking designs with its CNC router feature or tackling complex 5-axis operations.

LinuxCNC software can run all sorts of machines, like mills, lathes, and laser cutters. While it doesn't come with built-in CAM features, it can take G-code inputs. It is very important for me since G-code is my go-to format for many projects.

Now I use LinuxCNC to build my own CNC router machines. Some of the most common routers that I can make with LinuxCNC are woodworking routers. Thanks to its open source nature, all you have to do is download the software, get my router machine, and load the program to it. It also comes with a comprehensive manual, so grasping its functionality was easy. Besides, you can take advantage of multiple tutorials on the web to understand how different features and tools of this CNC router software work.

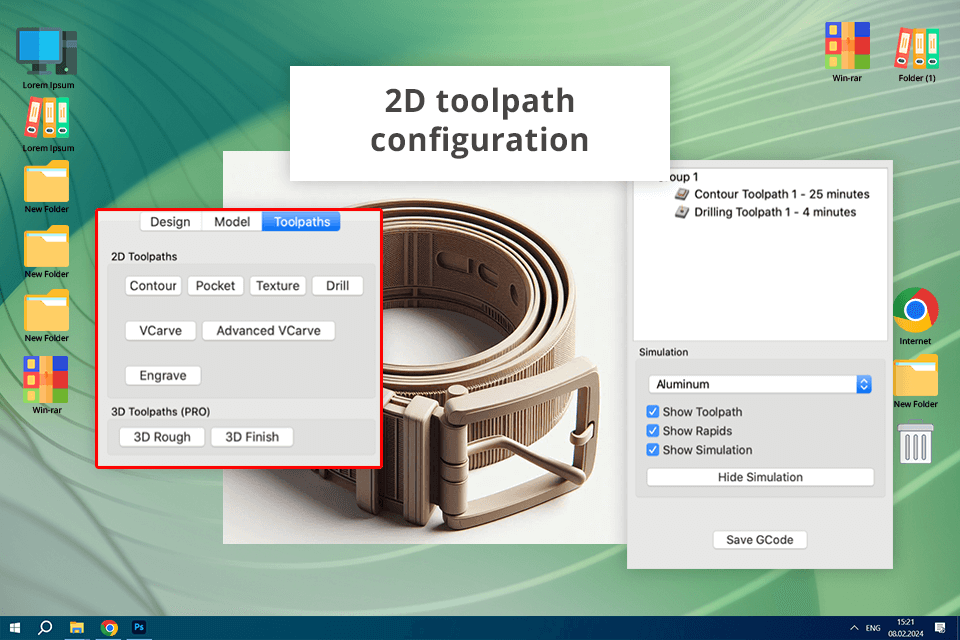

Carbide Create software is a favorite of hobbyists and small businesses because it's easy to use and affordable. It's a 2D CAD/CAM program for CNC routers that works great for novices and people engaged in simple projects.

It was the first CNC software I used at the start of my career, and I think it's the best CNC software for beginners seeking basic functionality.

Carbide Create comes with all the essential CNC designing and prototyping tools. Therefore, you can create vector shapes and manage cutting paths efficiently. It can also directly produce G-Code for the CNC machine to create a specific project.

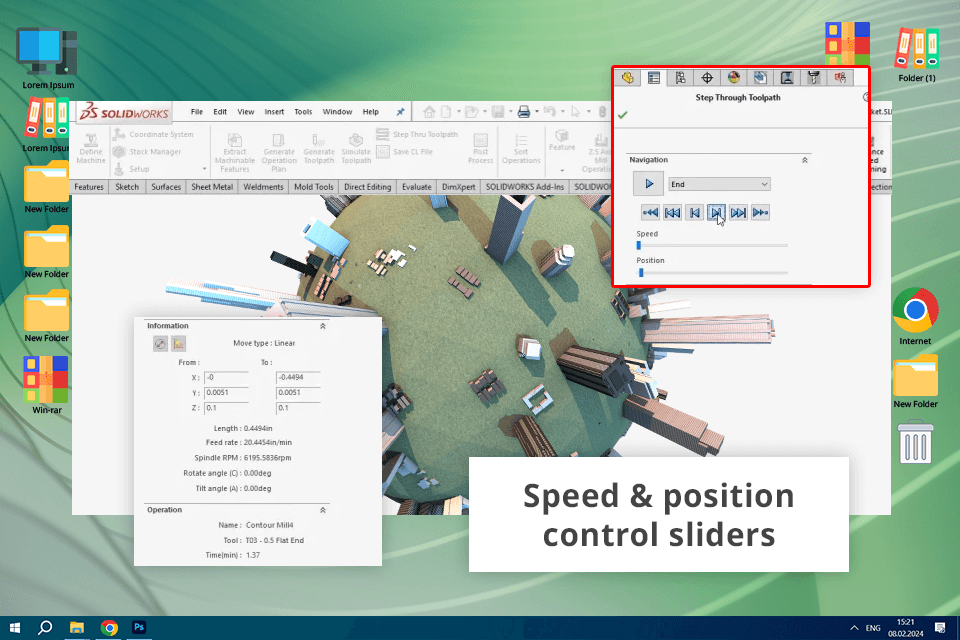

SolidWorks is free CNC software that is very popular in manufacturing. It offers powerful features that are in high demand among pros hunting for top-tier CAD/CAM software for CNC tasks. I rely on it too for making mechanical bits and pieces for complex machinery in various industries.

SolidWorks provides a holistic approach to design and manufacturing. It is capable of making detailed 3D models with its CAD software tailored for CNC, accurately simulating real-world physics, and more.

The most impressive feature is that the program can make intricate components and assemblies. Therefore, it is a perfect option for enterprises engaged in manufacturing sophisticated machinery. Most of all I like the inclusion of SolidWorks CAM – its dedicated CAM software, which integrates perfectly with the CAD suite.

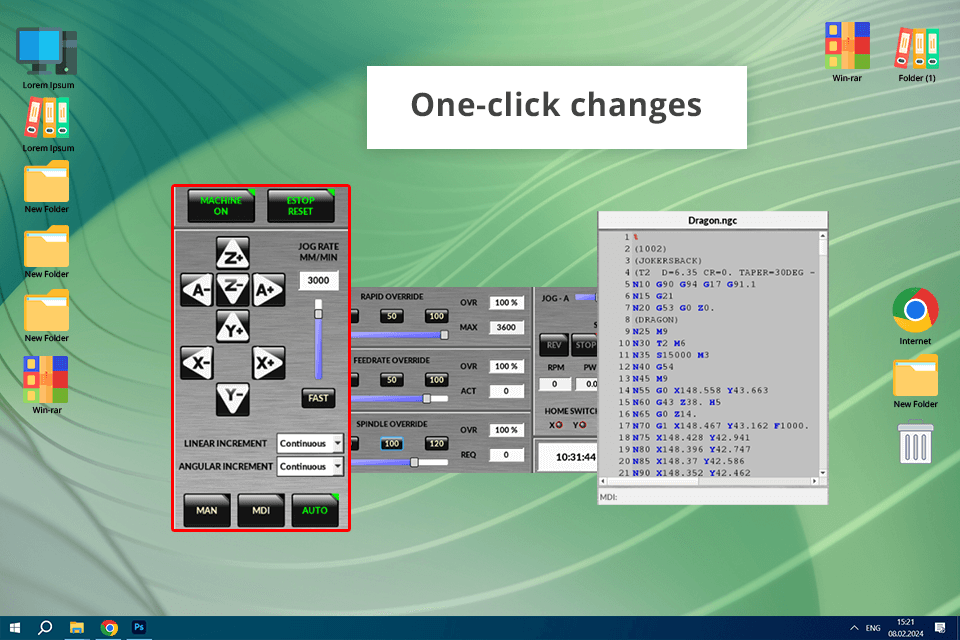

To evaluate the capabilities of Mach 3, I made a variety of designs using another CAD program and saved them in G-code format. It was very easy to upload them to Mach 3 thanks to its compatibility with the standard G-code. The interface is very user-friendly, so you can quickly upload, preview, and tweak the G-code. In general, the software offers decent control over the machining operations.

After uploading the designs, I run the CNC machine. Mach 3's control interface is user-friendly. There are options for real-time monitoring and manual adjustments. I experimented with a range of projects, including engraving, cutting, and 3D milling. I was very pleased with the results. The toolpaths were accurate and consistent.

Easel is designed to be used by manufacturers in building high-quality wood routers. I think this is the best CAM software for CNC both for beginners and experts in woodworking as it allows to create and modify woodworking router drawings without any complexity. Typically, similar programs have confusing functionality, but this isn’t the case with Easel.

It is great that it can be used in a variety of router machines such as those used for cabinet and table saw cutting. The 3D printing software allows the operator to manipulate all the machine's parameters, which include operating speed, material type, programmable depth, programmable slew rate, and much more. Thus, I can bring all my ideas to life keeping the accuracy on point.

I wanted to see if AutoCAD could be used for CNC work, so I began by making a very detailed 3D model. The software has lots of great 2D and 3D drawing tools. Thanks to them, I managed to create intricate details, preserving the desired dimensions. One thing I really liked was that I could use both a set way of designing and a more flexible approach. It is very important for creatives like me.

Once I finished designing, I saved the file in a format supported by CAM software, namely, DXF or DWG. Exporting was easy. The resulting files very of high quality, featuring the details and accuracy of my original design. Then, the CNC machine used the G-code made by AutoCAD to create the part exactly as I planned it.

Inkscape may not fit the bill as your typical CAD/CAM software, but it sure knows how to make 2D designs that can be sent to other software to generate G-code for CNC jobs. It supports various file types like SVG, PNG, and PDF, and offers impressive functionality. That’s why, I believe it can suit different users.

You can expand the capabilities of this free CNC software with G-code extensions to make designs fit for CNC machines. I sketch out my idea in Inkscape, then switch on an extension to transform it into G-code that a CNC machine can comprehend. It's extremely helpful, especially for tricky projects. So, if you want to make intricate 2D designs for CNC machining, I highly recommend using this tool.

If you're on the hunt for the best free CNC software, FreeCAD is the way to go. With this program, you can create precise milling tool paths and enjoy integration with different CAD programs. It's perfect for CNC newbies dipping their toes into milling or for hobbyists tinkering away on their own projects.

This CAD/CAM software for CNC routing and milling simplifies intricate 3D geometrical tasks through its intuitive graphical interface. Though it lacks some advanced features found in premium alternatives, it is still popular thanks to its user-friendly interface and great features.

To make sure GRBL Candle works well, I tested it on different types of CNC machines, from simple to medium ones. It offers real-time feedback and monitoring, so I can keep a close eye on the machining process. I can watch how fast the spindle is spinning and how quickly the material is moving. Therefore, I can adjust settings and achieve precise results on the first attempt.

To make work easier, GRBL Candle lets you make your own shortcuts and buttons. It means you can speed up repetitive tasks and get quicker results. For instance, you can set specific tools, expedite a sequence of commands, and more.