Can’t decide AutoDesk Fusion 360 or SolidWorks? Let’s compare both programs in detail.

Using Fusion 360, you may perform 3D modeling of separate details before you combine them into one file.

SolidWorks, on the contrary, uses a multi-component system of details where all elements are gathered in one file allowing engineers and designers to carry out their work with minimum effort.

Project check for external influence. If you work with AutoDesk Fusion 360, you may check your detail for resistance to external influence. You may do this with the help of static voltage analyses, thermal analyses, curvature and optimization of form.

It should be done to identify the most vulnerable places of the future product and correct them at the projecting stage.

Advanced net modeling. With AutoDesk Fusion 360, you may scan a real object and import this STL or OBJ file for a future 3D model. Then, using net modeling, you may shift or lengthen the points along the surface to create an organic geometry and surfaces.

Moreover, you may create a spline surface replicating the net profile and link the peaks of the spline to the net surface.

Huge library of engineer details. In the Fusion library, you may find, for example, an M6 screw 20mm long as well as nails of various lengths, springs, etc. These details may be used as a base of a new project or as a component of the existent model not to waste time on creating everything from scratch.

Flexible adjustments of the detail assembly. You may assembly details in the environment where they were created. While joining the details, you may choose different types of joints, from the simple hard to the advanced ones, like rotating, reciprocal, plane, spherical, screwed, etc.

You may also set the limits of their movement as in real life to see the animation of the dynamic movement of your assembly.

Modern milling tools. Thanks to modern milling tools, like spherical end mill, chamfer, perforator and etc., you may carry out the processing of any type ‒ processing of the plane surface, chases, ledges, cleaning of the surface, and more. You may also perform 4 and 5-axis processing of your details using CNC axial machine-tool.

Integration with Autodesk products. Creating a top-level project, you may use AutoCAD to develop a bold design. Then, transfer your project to AutoDesk Fusion 360 to create a 3D model of your project. After that, transfer data to Print Studio to work directly with a 3D Autodesk Ember printer.

Requires permanent Internet access. AutoDesk Fusion 360 stores all its data on the cloud. On the one hand, cloud storage can be accessed from average computers. On the other hand, you should have a permanent Internet connection to effectively work in the program.

64-bit processor is required. If you use a 32-bit processor, you will not be able to work in AutoDesk Fusion 360. You should have a 64-bit engine that features not less than 4 cores.

Work with flexible components. Working with SolidWorks, you may use the tool called “Make a Detail Flexible” that allows you to transform any detail into a dynamic one. For example, a spring may be in the compressed and free state; you may use articulated joints, crimped pipes and other assembly elements. You don’t have to create separate files of the details and unique configurations anymore.

Advanced 3D printing. SolidWorks uses an extensive library of 3D printers with characteristics of each device. Files are saved in 3MF format that stores data on 3D geometry, materials, colors, textures and more; it is very convenient to perform 3D printing. That is why you should invest in the efficient 3D printer.

Moreover, SolidWorks provides tools for simulating the behavior of 3D-printed parts based on the selected material. This helps users anticipate potential challenges, such as warping or structural issues, before sending the model to the 3D printer.

Accelerated work with 2D drawings. In the detailization mode, drawings are opened in a matter of seconds. You may change the existent designations and notes, indicate sizes, add technical requirements, create new papers and etc. Zoom and panorama are applied smoothly; it is very convenient to review and check projects.

Convenient work with envelopes. Using the tool “Assembly Envelope”, you may simplify the top-down design. You may use the envelopes to create the reference data not in one assembly, but in many. Now you may choose the components of assembly units and include them in the final assembly as envelopes.

Accelerated creation of sketches. The creation of sketches in SolidWorks is carried out in a quicker way thanks to the usage of sensor devices. Using silhouette objects, you may create sketches, projecting contours of the details onto the surface. However, make sure you have the best computer for SolidWorks to get the most out of the program’s capabilities.

Innovative work with nets. While editing the net in STL files on the edges, you may add the rounding; the rounding may be also transformed in chamfers and vise versa. You may perform all these operations using “Rounding”, “Chamfer”, “Mutual Cutting”, “Sew the Surfaces”, and “Delete a Hole” tools.

Works only on Windows. You may use this program only if you have Windows OS. The SolidWorks team is working towards solving this issue but so far, it is a huge minus. If you need 3D models compatible with iOS or Linux, use one of the free 3D models.

Complicated user interface. Since the program has many functions and tools, it is really difficult to master. That is why it’s recommended to watch some video tutorials or read comprehensible guidelines. This is exactly why SolidWorks is not the best variant for beginners.

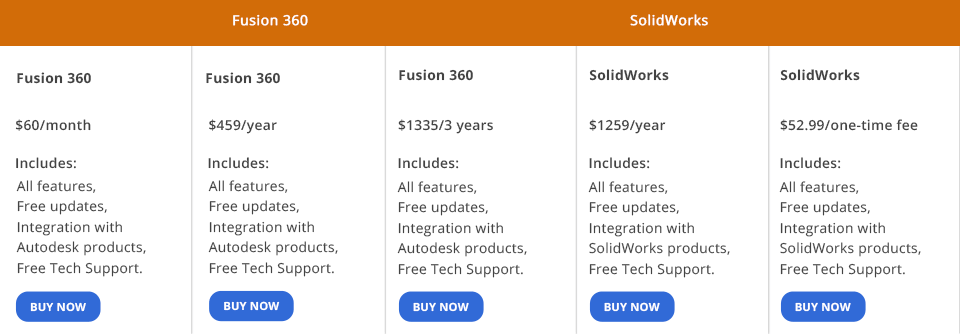

You may get a licensed AutoDesk Fusion 360 version in three ways. You may buy it for one month ($60), for a year ($459) and for 3 years ($1335). These licenses are not different in functionality; all options offer technical customers’ support, regular updates and other perks.

The subscription to SolidWorks Standard costs $3995. The annual subscription that includes technical support; updates and some other features are available for $1295.

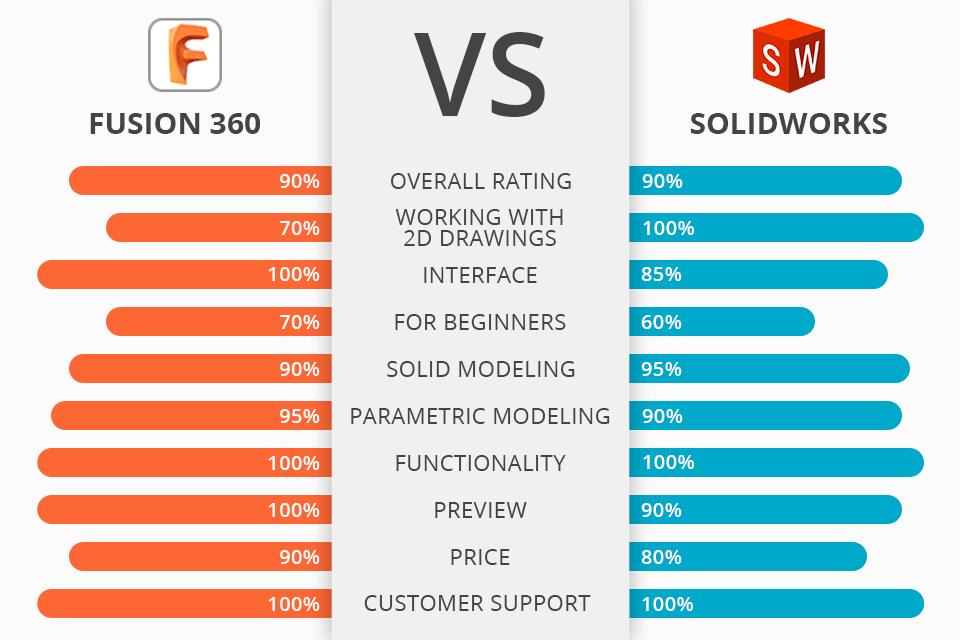

Having studied all the advantages of these programs, we may claim that there isn’t an absolute leader in the Fusion 360 vs SolidWorks competition. Both programs are used for 3D modeling but perform the task in different ways.

AutoDesk Fusion 360 is cloud-based software that would be more suitable for architectures and designers since it uses “one-file-at-a-time” approach. You may change this file at any projecting stage. You may create photorealistic images using various materials, like semi-transparent plastics, metal, glass and composites.

SolidWorks requires more space on the hard drive and works directly with the assembly. This software is more suitable for industrial tasks, engineering, ship-building and other enterprises. It has a big set of tools for 2D drawings.

In general, they will cope with the same task reasonably well but require different amount of time for this. That is why you should decide what purposes you need the software for, and make the right choice.